Manufacturing Sites Introduction

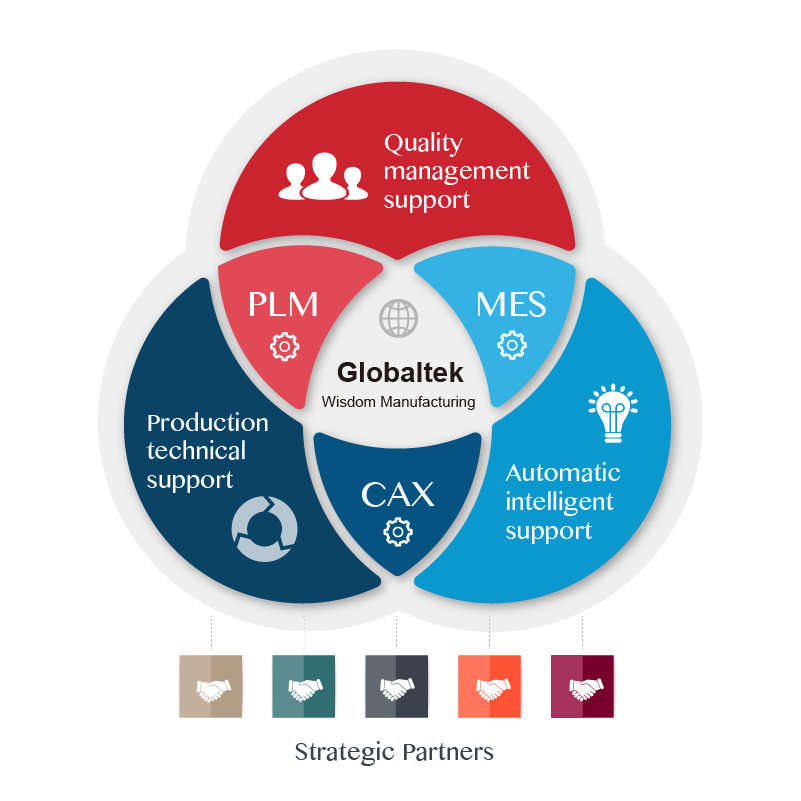

Global Tek Group has been striving her best to stay competitive by adapting the advance technology and skills since it was established. Although the Industry 4.0 is a major trend but it is required a vast resources to implement it even for a big organization worldwide, none of them can do it alone in a short period. We took initiatively and step by step to make it materialized starting from integration of CAX + PLM + MES till the entire information system and operations can work simultaneously toward to advance SMART manufacturing system .

As Global Tek’s market strategy is to focus on high end global niche market serving for automotive , industry control as well as aviation application globally , for any project , the engineering , technical ,manufacturing and quality control system starting from project is commenced till its end of life are equally important, hence the integration of the entire system and operation of all discrete processes in more systemic and simultaneous way are the key to gain more competitiveness , agility and efficiently !

As we mainly are working for high end niche market application where have high demand for quality and competitiveness. Either IATF16949 for automotive or AS-9100 required a severe quality control system even since the products is commend from the customers , To implement all the APQP and PPAP system are very timing and cost consuming especially for most precious engineering and technical human resource but it is a must not only to have it initially but also need to be implemented for all consequent manufacturing process in simultaneously and effectively way.

To cope with this big challenge , We form a dedicated lean center team and collaborate with external various intelligent system providers to build Global Tek;s smart manufacturing system starting from the very basic operation , but step by step persistent development , we can build a SMART network system entirely starting from CAX(CAD/CAM)+PLM+MES+ERP+SFC+SPC etc .Although it is one of big and long term investment , however we firm believe if we can take more proactive thinking , we will have more competitive edge in the long run.

In the mass production process, material identification by MES with Barcode, as well as being able to grasp in real-time the progress of product processing and tracking production scheduling, all of this helps to improve production efficiency and to increase production line strain capacity. If combined with the machine to monitor the digital recording of production history, this is useful not only for immediate control of production conditions, but it can also be used as a follow-up process to improve the basis. Through MES machine monitoring we can also keep tabs on the production conditions on both sides of the strait. Through the digitalization, we can improve the traditional factory management capacity information in the decision-making process, so that the group can consider the whole plant capacity to make the best correction.

MES is combined with IATF16949 and AS9100 quality systems to control the processing quality. Real-time measurement data to do real-time SPC calculus and then cascading CAX engineering data for intelligent compensation logic judgment and dynamic calculation compensation value will reduce the product re-employment rate while improving the yield. Thanks to MES digitalization and systematization, Global Tek Group has managed to solve all quality control as well as production management issues, in this way it has gained a firm position in the international market.